About Us

EMAC Group Limited was established in Hong Kong in 2010, aims to become a solid one-stop supplier in the power machinery industry. EMAC operating four overseas subsidiaries and owns 10 self-registered trademarks, our products are widely used in which covers energy, maritime, automotive, construction, railways and spare parts. Based on different types of Gummins engines, EMAC integrate other leading power system products into a complete power system.

With years of rich powertrain supply experience, EMAC can quickly understand and respond to customer needs, greatly reducing customer communication costs.

EMAC provides one-stop solutions covers from pre-design to components supply, from installationand integration to after-sales service. Our comprehensive services ensure seamless operation and maintenance of power systems across diverse industries.

Leading Products

Products are widely used in commercial vehicles, construction machinery, power generation equipment, ships, railways and other industrial fields. Its main products cover many types of engines, generator sets and components, as well as new energy power systems that have developed rapidly in recent years.

The main products meet the emission requirements of Stage 2 and Stage 3 (Euro 2 and Euro 3) for on-road diesel engines specified by Chinese national standards, American standards and European standards, as well as Stage 1 and Stage 2 emission requirements for off-highway diesel engines (Tier 1 and Tier 2). The engine power range produced by CCEC is 200HP-1600HP. The products are mainly used in heavy-duty vehicles, large passenger cars, construction machinery, mining machinery, petroleum machinery, rail machinery, port machinery, stationary and mobile diesel generator sets, power stations, ship propulsion Power packs and auxiliary power packs, pump power packs and other power packs.

Technical Advantages

CCEC diesel engine is developed and designed according to the advanced heavy-duty engine technology concept. It has the advantages of high reliability, good durability, good fuel economy, small size, large power, large torque, large torque reserve, and strong component versatility.

Service System

The company’s product technology, manufacturing technology and application technology develop synchronously with the American CCEC Company, and develop and manufacture products with leading power, economy, reliability, durability, safety and environmental performance according to the characteristics of the Chinese market.

Quick service system established in accordance with CCEC international standards: respond to users within 30 minutes of receiving user information and determine a service response plan; dispatch service personnel to the scene within 4 hours; establish a 24-hour customer service hotline.

Implement quality assurance and warranty commitments consistent with CCEC International Standards.

Sound national service network: 10 regional maintenance service centers, more than 100 maintenance service agents and service stations, more than 600 professionally trained service technicians, and a fully functional CCEC East Asian high-power engine user training center.

Management System

Quality management system. In 1999, the company obtained the ISO9001: 94 certification issued by the French BVQI; at the end of 2002, it obtained the BVQI ISO9001: 2000 version certification; in 2006, it obtained the BVQI ISO/TS16949: 2002 quality certification.

Standardization of safety and quality. In 2006, it passed the national safety and quality standardization review, and the State Administration of Work Safety issued a document to approve our company as a “national first-class safety and quality standardization” machinery manufacturing enterprise.

Occupational health and safety and environmental management system. The company obtained the OHSAS18001/ISO14001 certification from the French BV in early 2008, and obtained the OHSAS18001/ISO14001:2007 certificate through the revision audit in early 2009; in early 2009, the company obtained the French BV’s ISO14001 certification.

Major Awards

N series engines were rated as China’s national high-quality products (silver award); N and K series engines and generator sets were rated as the first batch of famous brand products in Chongqing. The company has won the top 50 industrial enterprises in Chongqing for 15 consecutive years and the title of “Top Ten Foreign-Invested Enterprises in Chongqing” for 6 consecutive years.

.jpg)

More Features of the CCEC Engines

Low Fuel Consumption and Good Economy

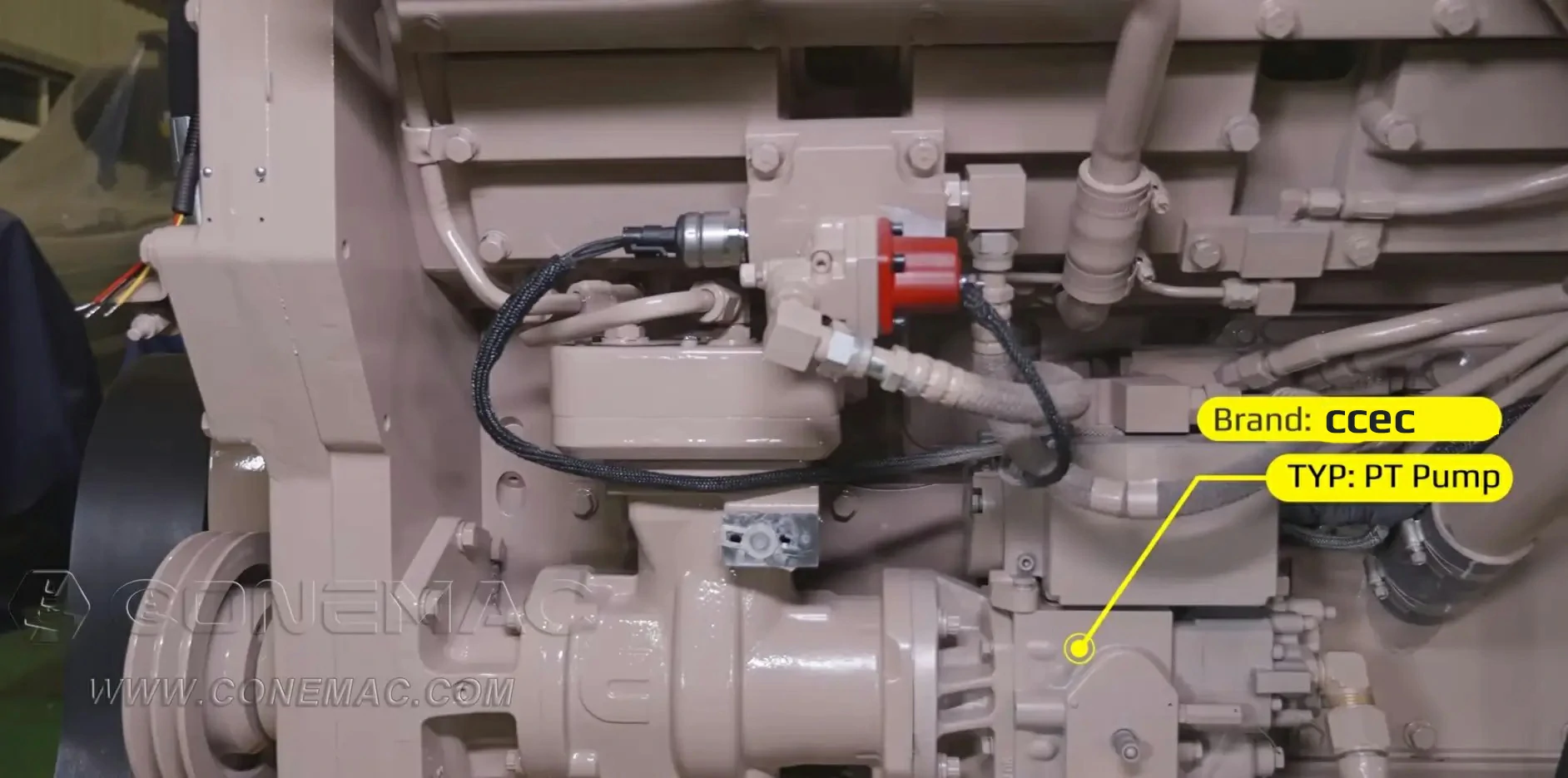

CCEC patented PT fuel system and ultra-high injection pressure ensure that the engine has good atomization and full combustion.

The high-efficiency Holset exhaust gas turbocharger can ensure more sufficient intake air, improve engine efficiency, further improve combustion, and reduce engine specific fuel consumption.

Air-to-air cooling technology ensures more adequate intake air and better fuel economy.

Compact Structure and Easy Maintenance

The wet cylinder liner can be replaced, with good heat dissipation effect and easy replacement.

The parts of all models have strong versatility, high degree of serialization, and easy maintenance.

Both the cylinder block and the cylinder head adopt built-in pressure lubricating oil passages, with compact structure, low failure rate, advanced design and reliable performance.

Cylinder block: Made of high-strength alloy cast iron, with good rigidity, low vibration and low noise.

Cylinder head: Four-valve design per cylinder, optimized air/fuel mixing ratio, effectively improve combustion and emissions; one head per cylinder, easy maintenance.

Camshaft: The single camshaft design provides precise control of valve and injection timing, and the optimized cam profile reduces shock force and improves reliability and durability.

Crankshaft: One-piece crankshaft made of high-strength forged steel, the induction hardening process of rounded corners and journals can ensure higher fatigue strength of the crankshaft.

Piston: Using the latest aluminum alloy casting technology, the design of ω-shaped head and barrel-shaped skirt can compensate for thermal expansion and contraction, ensuring a good fit.

Professional Configuration Best Quality

Lubrication system: All moving parts are forcibly lubricated; large-capacity gear pump provides pressure lubricating oil to lubricate bearings and cool pistons; oil cooler, full-flow filter, bypass filter maintain good oil condition.

Fuel system: CCEC patented PT fuel system, optimized combustion, surging power; STC distributed timing system to ensure better combustion under all working conditions; low-pressure fuel supply system, equipped with a one-way fuel circuit, safe and reliable.

Cooling system: Gear centrifugal water pump is used for forced water cooling, large-flow water channel design, and good cooling effect; spin-on water filter and special DCA additives can effectively prevent rust and cavitation, control the acidity of the coolant and remove impurities.

Intake and exhaust system: efficient Holset exhaust gas supercharger further improves combustion; pressure pulse exhaust pipe can make full use of exhaust energy and improve engine efficiency; air-to-air cooling technology ensures better fuel economy and emissions.

Mature Products, Famous all over the World

Wide range of applications: Since CCEC entered China in 1975, CCEC series engines have been widely used in construction machinery, heavy vehicles, power generation, marine power and other fields; it has formed strategic partners with important customers.

High reputation: As one of the main models of the CCEC family, CCEC series engines have won high recognition from customers in various fields for their strong power, ultra-low fuel consumption, high reliability and low maintenance costs.

Technology upgrades: Air-to-air cooling, slow start and other technologies further improve the reliability, power, fuel economy and emissions of the engine. The engine launched in 2008 adopts electronic fuel injection technology, with a power of 227-1329kW, which can meet the third-stage emission standard of non-road mobile machinery, further enhancing CCEC’s leading position in China’s high-horsepower engine manufacturing industry.