Truck transportation is one of the important links in the current open-pit mine production process. Rigid mining trucks have always dominated the large open-pit mine transportation market with their large-scale equipment, large-scale equipment, and long depreciation cycle. Around 2005, domestic car companies combined the market status and vehicle usage conditions to develop an off-road wide-body dump truck by increasing the chassis structure strength of highway dump trucks. This model has the advantages of low production cost, fast equipment update, and low maintenance cost. The market share has increased year by year, and there is a trend of replacing rigid mining trucks.

At present, in the transportation operations in open-pit mines, rigid mining trucks and wide-body trucks are the absolute main models, and they undertake the task of ensuring supply and production in the mines. In terms of operational capabilities, which one is better? This article analyzes and compares the above two models from the dimensions of power, deadweight coefficient, and other dimensions of mining truck performance-related indicators, so as to provide a reference for the mine party when selecting vehicles.

Throughout the history of open-pit mining equipment development, mining and transportation equipment has been developing towards large-scale development. Since the 1960s, 100t, 200t, and 300t mining trucks have appeared one after another. The 75710 giant mining truck produced by BELAZ in Belarus is equipped with two high-power engines and has a load capacity of 450t, making it the largest tonnage mining truck in the world today.

Development History of Mining Trucks

1. Brief History of Rigid Mining Trucks

With the continuous development of truck manufacturing technology, on January 27, 1960, Unit Rig, USA, cooperated with General Electric GE to successfully develop the first electric wheel prototype and began mass production. After entering the market, it was a great success; and in the second half of 1963, it began mass production of the M85 85st (77t) electric wheel dump truck. As mining trucks are moving towards large-scale iterations, two types of models have gradually been formed: mechanical transmission mining trucks and electric wheel mining trucks. The load capacity of mining trucks has also developed from the initial 50t to 60t to the current 300t or more. Except for Caterpillar, which still uses mechanical transmission for large-tonnage rigid mining trucks, other mining truck manufacturers basically adopt the electric transmission technology route.

2. Development History of Off-Highway Wide-Body Vehicles

Before 2005, open-pit mines were mainly based on ordinary highway heavy trucks, but due to the special working conditions and environment of the mining area, heavy trucks were difficult to meet the operating requirements of the mining area in terms of load-bearing capacity, driving performance, passability and safety. After 2005, domestic truck manufacturers strengthened and widened the body structure based on the original dump trucks, and designed and produced off-road wide-body vehicles, which have the characteristics of large one-time loading capacity, high transportation efficiency, low maintenance cost and good profitability.

After 2012, the mining truck market entered a trough period, and the industry experienced a major reshuffle. Some small factories were eliminated first. After 2015, the market gradually entered a mature period. Many domestic OEMs have the ability to design and produce wide-body vehicles. It can be said that wide-body vehicles have entered a golden period of growth.

To date, the chassis technology of wide-body vehicles has become increasingly mature, and the speed of product updates has kept pace with the intensity of market competition. In addition, the vehicle performance is basically stable, making it the preferred model for open-pit mining transportation operations, and the annual domestic sales volume remains above 20,000 vehicles.

Comparison of operational capabilities

There is room for wide-body trucks in open-pit mines with a capacity of hundreds of thousands to millions of tons, and most large open-pit coal mine surface soil stripping projects are also mainly based on wide-body trucks. Although the two types of mining trucks have their own advantages and characteristics in terms of design and cost performance, they also have their own limitations and shortcomings in practical applications.

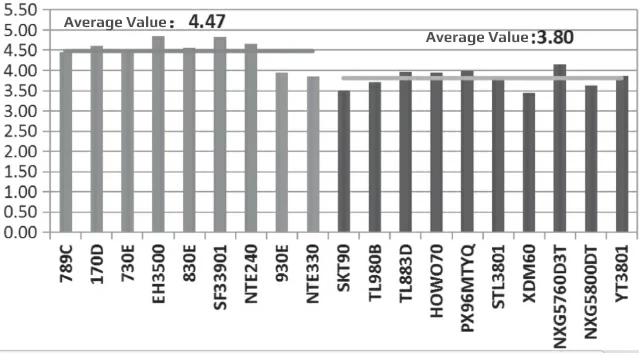

The following is an analysis and comparison of the operational capabilities of the two types of mining trucks by comparing the performance-related indicators of power and deadweight coefficient.

In Conclusion

Comparing the operating capabilities of the two from three aspects: specific power, self-weight coefficient and equipment update cycle, the rigid mining truck, as a transportation equipment specially designed for mine production, has obvious advantages in power indicators and climbing ability, and is suitable for bumpy road conditions in open-pit mines. and high workload requirements.

A single rigid mining truck has a strong carrying capacity, and when used with large-scale electric shovel operations, it has significant scale effects, can reduce the amount of equipment investment, and facilitates production organization and on-site management. It has more advantages in open-pit coal mines and metal mines with high output requirements and large amounts of mining and stripping work. In addition, the equipment update cycle is long and the production capacity is relatively controllable, which can ensure the continuous efficient and stable operation of large mines.

From an economic perspective, wide-body vehicles are undoubtedly more cost-effective and have a shorter investment recovery period, making them more suitable for medium and large-scale sand and gravel aggregate mines in the south. In the future, 70-ton diesel wide-body vehicles will not be eliminated for the time being, but will continue to be upgraded and iterated to meet exhaust emission requirements and improve driving comfort.

But when we enter the era of new energy mining trucks, we are faced with new problems. New models of large-power 100-ton wide-body trucks are launched one after another and are valuable. The price of a 90-ton hybrid wide-body mining truck is close to more than 2 million yuan. It can be seen that once the mining truck is “electrocuted”, it will become unaffordable for you.