As the main transportation equipment in medium and large open-pit mines, when should an old mining truck that is approaching the end of its service life be decommissioned to maximize its economic benefits? This has become the most concerned and difficult issue for equipment management departments of many mining companies.

Taking TEREX TR50 as a sample, we will explore the standards for decommissioning mining dump trucks in open-pit mines, and discuss the impact of each decommissioning condition on the use of equipment, and then explore when to decommission rigid mining trucks to maximize corporate benefits.

Rigid mining trucks are favored by many open-pit mines due to their strong carrying capacity, high transportation efficiency, and ability to adapt to complex road surfaces in open-pit mines.

As the main transportation equipment in open-pit mines, the high or low maintenance cost and the length of their service life determine the economic benefits of mining companies.

To this end, this article starts from the actual situation, takes the mining dump truck that Hualian Zinc Indium Company once served as an example, analyzes the factors affecting its decommissioning, and explores the best decommissioning conditions for mining dump trucks.

1. Vehicle safety performance

1.1 Frame

A rigid mining truck frame is good, which is the foundation for its good operation. All major systems and parts of the vehicle are installed on the frame, so a stable frame is the key to the safe operation of transportation equipment.

The company’s existing TR50 mining trucks have two frames. The TR50 mining dump truck frame purchased in 2008 is a general-purpose frame, and the TR50 mining dump truck frame purchased in 2011 is a reinforced frame.

Since the vehicle was put into operation in the mining area, the TR50 mining dump truck frame purchased in 2008 has frequently failed, especially since 2015, the frame, ring beam, and rear axle housing have cracks of varying degrees, and the same position has been broken and welded repeatedly for many times, and the maintenance cost has gradually increased, which is close to the vehicle decommissioning standard.

1.2 Braking system

The open-pit mining site has complex lines and many large equipment. A good braking system is the basis for the safe operation of mining trucks.

The company’s existing TR50 mining dump trucks use pneumatic drum brakes, which are characterized by long effective braking distance, easy heating, and a sharp drop in braking performance during continuous use.

Since its operation in 2008, its brake operating valve, distribution valve, one-way valve, air reservoir, brake cylinder, pipeline, brake push rod, etc. have aged and leaked to varying degrees, posing safety hazards.

The production routes in the early stages were mostly heavy-loaded downhill sections, and the braking effect of the vehicles was already stretched. From 2015 to 2019, the workshop’s existing TR50 mining dump trucks had accidents every year due to unsatisfactory braking effects or sudden damage to a certain brake component.

The braking effect of the TR50 mining dump truck has had a certain impact on the safe production of the workshop.

1.3 Steering system

The TR50 mining dump truck has been in service in the company from 2008 to 2017. The vehicle steering system has been in good use. Since 2017, after 9 years of operation, its steering tie rod, hydraulic cylinder ball head and locking nut and other parts have been damaged to varying degrees, causing the equipment to be shut down for maintenance for 1-3 days.

The workshop has formulated relevant replacement standards for this, requiring workshop equipment management personnel and maintenance personnel to conduct daily inspections of operating equipment and report problems in a timely manner. And pay special attention to parts that are approaching the end of their service life, replace damaged parts in a timely manner, and eliminate safety hazards.

The TR50 mining dump truck has been in operation for 12 years since it was used in 2008 (2020). The vehicle is in good overall operation, but with the aging of the equipment, the vehicle frame, braking system, and steering system are approaching the end of their life, and there are certain safety hazards.

The company has gradually purchased new mining equipment such as TR100 and TR100A, and deployed TR50 mining dump trucks to relatively flat sections of the mine for transportation to ensure the safe operation of the workshop.

2. Analysis from the perspective of economic efficiency

2.1 Spare parts consumption

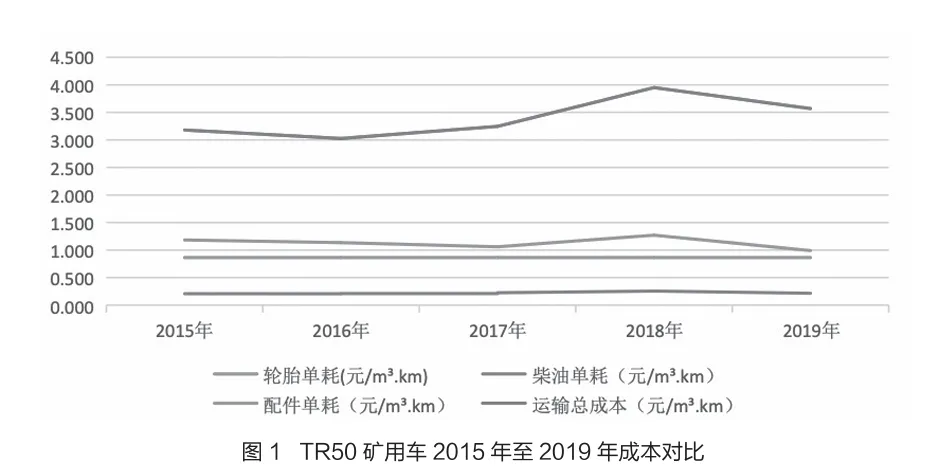

Before 2017, the fluctuation of spare parts consumption was not obvious. Since 2017, spare parts consumption has increased significantly year-on-year. The main reason is that the equipment has been in operation for 10 years by 2018, and the parts of the equipment are seriously aging. The service life of large parts such as engines and gearboxes has been shortened, resulting in a shortened overhaul cycle and increased costs.

2.2 Fuel consumption

Before 2017, fuel consumption did not fluctuate much. Since 2017, it has increased by about 10% every year, with the highest increase in 2018, about 20%. The main reasons include equipment reasons and external reasons.

Equipment reasons: After the engine has undergone an overhaul, the wear of some non-wear parts has increased, and the wear of injectors, fuel pumps, etc. has increased, increasing fuel consumption.

External factors: The company is located on the border between China and Vietnam. Due to the natural environment, the rainy season in 2018 was long and the road surface in the mining area was poor, which led to increased fuel consumption.

2.3 Tire consumption

During the use of the vehicle, there was not much change in the tire consumption.

2.4 Total direct cost consumption

Since 2015, there has been a clear upward trend every year, reaching a high point of 3.95 yuan/m3·km in 2018. In 2018, the equipment had been in operation for ten years and reached a critical point. Many parts were replaced, resulting in rising costs.

From the perspective of economic use, the total direct cost of the vehicle can be controlled below 3.5 yuan/m3·km in the future. Considering the economics of the equipment, it can continue to be used. If the total direct cost exceeds 4 yuan/m3·km, it is recommended to gradually eliminate and stop using the equipment.

3. Conclusion

Based on the above analysis, three standards for the decommissioning of mining dump trucks can be summarized:

3.1 Vehicle safety

The most important thing for the development of mining is to ensure that production is carried out under safety belt conditions, so the safety performance of equipment is also a top priority.

Open-pit mines have complex routes and a large number of large-scale transportation equipment. If during operation, the transportation equipment has frequent frame failures, poor braking effects, and insensitive steering that is difficult to repair, it is recommended to decommission it.

3.2 Economic use

Combined with the actual situation of the enterprise, if the spare parts cost, maintenance cost, fuel unit consumption and other consumption of the equipment continue to increase, it is recommended to decommission it when the investment cost is close to 80% of the output benefit.

3.3 Equipment integrity rate and attendance rate

With the aging of equipment, the frequency of equipment failures increases, resulting in a significant decrease in equipment integrity rate and attendance rate. When the annual average equipment integrity rate is lower than 60% and the annual average attendance rate is lower than 30%, it is recommended to decommission the equipment.