Comparison of Engine Basic Parameters

Displacement and Power

The 16V4000C01 series engines have a displacement of 64L, while the QSK 60 has a displacement of 60L. The larger displacement gives the 16V4000C01 series an advantage in power output, enabling it to provide more robust power for mining trucks and meet the operational requirements in complex mining conditions.Weight and Volume

In terms of weight, the 16V4000C01 engine weighs 7.1 tons when wet, and the QSK 60 Tier 1 weighs 8.6 tons. The 16V4000C01 is 15% lighter. In terms of dimensions, the 16V4000C01 is smaller than the QSK 60 in length, width, and height, with a 30% smaller volume. The lighter weight and smaller volume not only reduce the self – load of the mining truck but also enhance the vehicle’s maneuverability and flexibility to a certain extent.- Reduced tire wear / Increased load – carrying capacity

- Better fuel economy

- Low vibration; Low noise; Smoother engine operation

| Comparison Items | 16V4000 Cx1 | QSK 60 Tier 1 |

|---|---|---|

| Engine Wet Weight (tons) | 7.1 | 8.6 |

| Length (mm) | 2799 | 1371 |

| Width (mm) | 2929 | 1629 |

| Height (mm) | 1735 | 2316 |

Comparison of Fuel Economy

Fuel Consumption/Displacement

The 16V4000C01 series achieves more horsepower output with a larger displacement while consuming less fuel. For example, at a power of 2700bhp, the fuel consumption of the 16V4000C01 is 197g/kWh, while that of the QSK 60 is 206g/kWh.

Load Factor and Fuel Savings

When the load factor is 30%, the 2700 – horsepower 16V4000C01 engine saves 6.5 liters of fuel per hour compared to the QSK 60. If a fleet has 10 electric vehicles and operates 7000 hours a year, the annual fuel savings can be as high as 455,000 liters of diesel.

Comparison of Fuel Consumption under Different Loads

The following table allows us to more clearly see the differences in fuel consumption of the two engines under different loads:

| The load factor is 30% | |||||

|---|---|---|---|---|---|

| Load(%) | Time(%) | 16V4000 | QSK60 | ||

| BSFC | FC/hour | BSFC | FC/hour | ||

| (g/kWh) | (L) | (g/kWh) | (L) | ||

| 100 | 17 | 197* | 81,3 | 206* | 85 |

| 80 | 13 | 191 | 48,2 | 200 | 50,5 |

| 20 | 15 | 210 | 15,3 | 217 | 15,8 |

| 0 | 55 | ~260 | 5,5 | ~260 | 5,5 |

Note: *Data for EPA 1 certified version meeting EPA I emission standards. It can be clearly seen from the table data that the 16V4000C01 has a better fuel consumption performance than the QSK 60 under various load conditions.

Under a load factor of 30%, the overhaul intervals for the 2500hp engines 16V4000 and QSK60 are as follows:

- Theoretical overhaul interval: 16V4000 is 27,000-30,000 hours, while QSK60 is 20,000 hours.

- Actual overhaul interval: 16V4000 is 24,000-27,000 hours, while QSK60 is 15,000-20,000 hours.

The 16V4000C01 has an advantage in terms of low fuel consumption and also demonstrates a longer overhaul interval compared to the QSK60, making it a superior performer.

In terms of maintenance convenience, the comparison between the 16V 4000-2700hp and QSK 60-2700hp is as follows:

- Turbocharger: The 16V4000 uses a single-stage turbocharging system with 4 turbochargers, while the QSK60 uses a two-stage system with 8 turbochargers.

- Intercooler: The 16V4000 is equipped with 1 intercooler, whereas the QSK60 has 6 intercoolers.

- Overall layout design: The 16V4000 has a simple design, while the QSK60 is more complex.

16V4000C03 standard daily maintenance cycle:

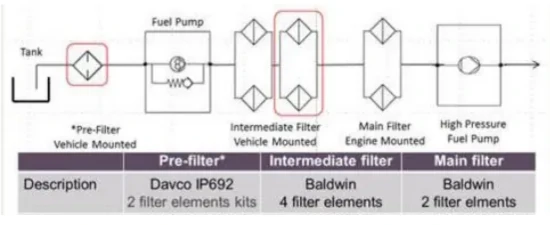

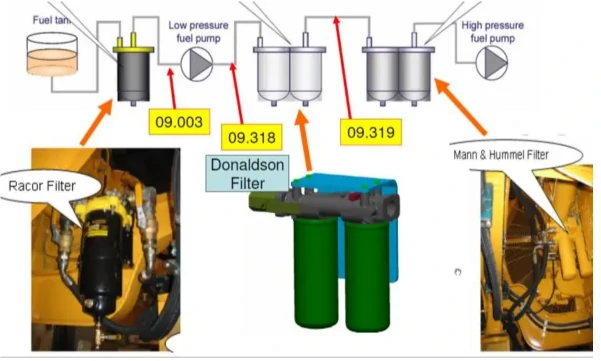

Replace every 500 hours, can be extended to 1000 hours maintenance; HEFF diesel filter system

Enhanced high performance (HEFF) three-stage diesel filter system:

16V4000C21 Vs QSK60 Advantages Summary

| Cummins QSK60 HPI 2700hp | MTU 16V4000C21L 2700hp | |

|---|---|---|

| Engine configuration | 16-cylinder V-type, 60L | 16-cylinder V-type, 64L larger displacement |

| Emission | No emission | U.S. EPA Tier 1 |

| TBO | 15,000-20,000 hours | 30,000 hours; 20-50% longer overhaul period 16V4000 has a higher price than QSK60 but saves annual costs.For a fleet of 30 units:QSK60 requires an overhaul every 4 years, at 5 units per year.16V4000 requires an overhaul every 6 years, at 5 units per year.This extends the overhaul cycle by 6-800 hours annually, increasing uptime and power availability. |

| Daily Maintenance | 250-330 hours | 500 hours; Longer maintenance interval Reduces oil consumption by 260L per service, 12 times per year. Saves 5000L oil annually, equivalent to 60,000 RMB. Also reduces overall maintenance costs and downtime. |

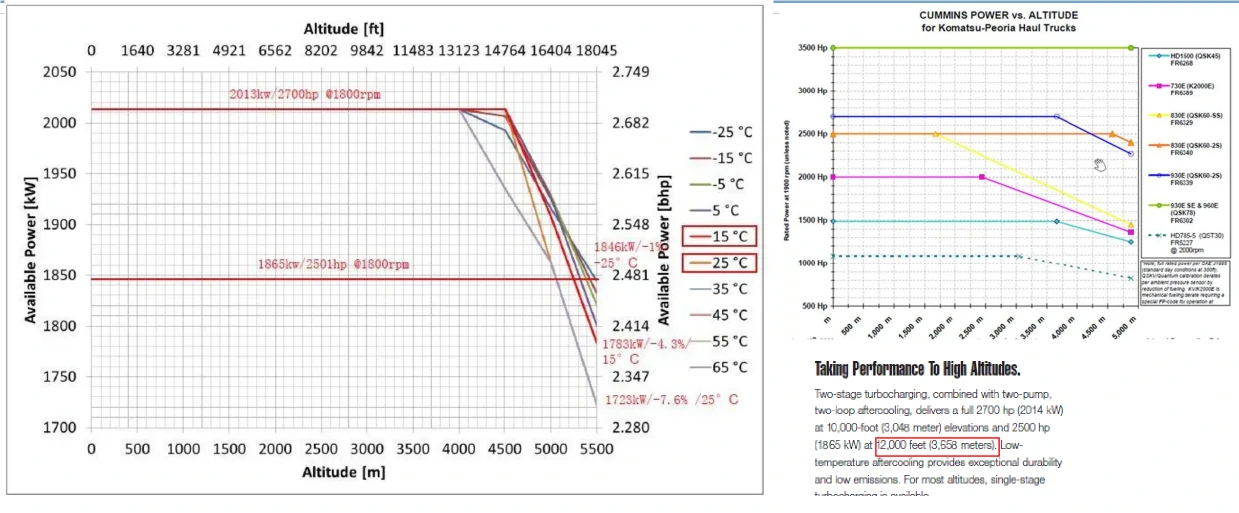

| Altitude capability | 2438m without power loss; Market recognizes applications above 4000m as high-altitude use. | 5000m without power loss, offering better high-altitude performance. |

| Weight | 100% | 93%; More fuel-efficient Saves 7% fuel per hour (~8L per hour). At 5000 hours, saves 4000L diesel, about 320,000 RMB. |

| Height (mm) | 100% | 85%, 1 ton lighter |

| Volume | 100% | 70%, smaller volume |

Conclusion: If calculated based on 30 300-ton mining trucks, the direct economic benefits can save operating costs every year: 8 million + 60,000 x 30 units + 320,000 x 30 units = 19.4 million RMB!!!

16V4000C03 and competitor QSK60 MCRS National III Tier 2 detailed comparison Compare

Displacement /Fuel consumption /Power reserve

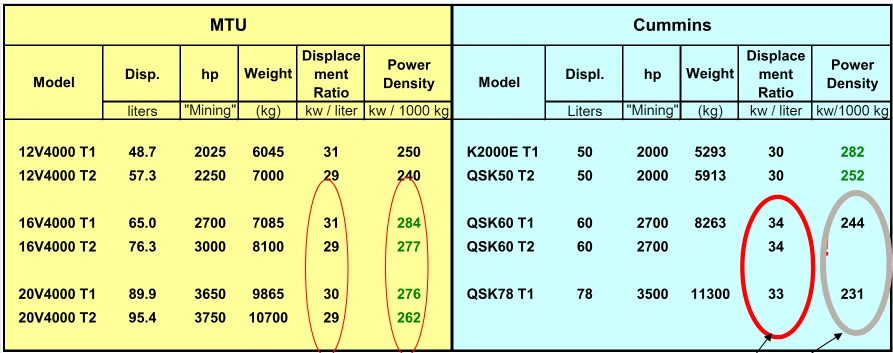

Power density

availability & Overhualing

Maintenance and Part exchange

Safety

Highland performance

Daily maintenance

Warranty Terms

16V4000C03 low fuel consumption leader Tier 2/National III emission model comparison

1. Displacement/fuel consumption comparison Power reserve

| 16V 4000Cx3 | 16V 4000 Advantage | QSK 60 Tier2 | |

|---|---|---|---|

| Larger displacement | 76L | Displacement increased by 26% | 60L |

| More horsepower reserve | 2500 bhp * | Power reserve increased by 12.3% | 2500 bhp |

| Less fuel consumption | 205g/kWh** | Fuel consumption reduced by 4% | 215g/ kWh ** |

Advantages: stronger power, lower fuel consumption, and improved vehicle productivity

* 16V4000 Cx3 Tier2 model has a maximum power of 3000hp; it has a larger power reserve than the QSK60 design with a maximum power of 2850hp; better plateau power reduction;

** EPA 2 certified version meets EPA 2 stage and National 3 stage emission requirements; after 1700rpm speed optimization

16V4000C03 Leader in low fuel consumption, no emission Model comparison

1. Displacement/Fuel consumption comparison Power reserve

| 16V 4000Cx3 | 16V 4000 Advantage | QSK 60 Tier2 | |

|---|---|---|---|

| Larger displacement | 76L | Displacement increased by 26% | 60L |

| More horsepower reserve | 2500 bhp * | Power reserve increased by 12.3% | 2500 bhp |

| Less fuel consumption | 200g/kWh** | Fuel consumption reduced by 7% | 215g/ kWh ** |

Advantages: stronger power, lower fuel consumption, and improved vehicle productivity

* 16V4000 Cx3 Tier2 model has a maximum power of 3000hp; it has a larger power reserve than the QSK60 design with a maximum power of 2850hp; better plateau power reduction;

** EPA 2 certified version meets EPA 2 stage and National 3 stage emission requirements; after 1700rpm speed optimization

16V4000C03 Low fuel consumption leader Tier 2/National III emission Model comparison

1. Displacement/fuel consumption comparison Power reserve

| 16V 4000Cx3 | 16V 4000 Advantage | QSK 60 Tier2 | |

|---|---|---|---|

| Larger displacement | 76L | Displacement increased by 26% | 60L |

| More horsepower reserve | 2500 bhp * | Power reserve increased by 12.3% | 2700 bhp |

| Less fuel consumption | 205g/kWh** | Fuel consumption reduced by 2% | 209g/ kWh ** |

Advantages: stronger power, lower fuel consumption, and improved vehicle productivity

* 16V4000 Cx3 Tier2 model has a maximum power of 3000hp; it has a larger power reserve than the QSK60 design with a maximum power of 2850hp; better plateau power reduction;

** EPA 2 certified version meets EPA 2 stage and National 3 stage emission requirements; after 1700rpm speed optimization

16V4000C03 Leader in low fuel consumption Tier 2/National III emission model comparison

2. High power concentration – low power displacement ratio

Benefits to customers:

• Reduced tire wear/higher load capacity

• Higher fuel economy

• Better engine reliability

16V4000 and 20V4000 outperform QSK60 and QSK78, which translates into more load capacity and higher reliability for mining vehicles.

16V4000C03 Leader in low fuel consumption Tier 2/National III emission Model comparison

3. Overhualing time comparison

Under the load factor of 30%, 2500hp engine Load factor 30%; 2500hp engine

| overhualing | 16V4000C03 | QSK60 MCRS |

| Theory | 27,000 hours | 20,000 hours |

| Actual | 21,000-24,000 hours | 15,000-20,000 hours |

4. Maintenance

MTU advantages

• Easy maintenance

• Low risk of maintenance errors

• Fewer parts

• Low cost of replacement

| 16V 4000C03 | QSK 60 MCRS | |

|---|---|---|

| Turbo stage | single | Two |

| Turbo Qty | 2 | 8 |

| Cooler | 2 | 6 |

| Configuration | simple | complex |

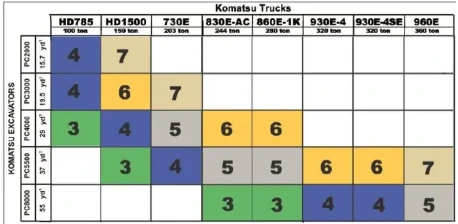

5.Parts Exchange

1. The three MTU models are developed on the same platform. The only difference is the number of cylinders, i.e. 12 cylinders, 16 cylinders, and 20 cylinders. Important parts such as pistons and cylinder liners are all common. Greatly reduces the spare parts reserve of users;

200-ton mining truck, 12V4000C03220-ton mining truck, 16V4000C03300-ton mining truck, 16V4000C03400-ton mining truck, 20V4000C03

2. Hydraulic excavators with tonnage above 300 tons all use

12V4000C03 engine. The use of mining trucks and excavators can further reduce the types of spare parts and spare parts reserves;

300-ton excavator, 12V4000C03400-ton excavator, 2x 12V4000C03560-ton excavator, 12V4000C03700-ton excavator, 2x 12V4000C03

| 12V4000C03 | 16V4000C03 | 20V4000C03 | |

|---|---|---|---|

| Power | 1193-1680kw 1600-2250hp | 1492-2240kw 2300-3000hp | 2375-3000kw 3185-4023hp |

| Engine displacement | 57.3L | 76.3L | 95.4L |

| Bore/Stroke | 170/210 | 170/210 | 170/210 |

| QSK50 | QSK60 | QSK78 | |

|---|---|---|---|

| Power | 1044-1567kw 1400-2100hp | 1343-2014kw 1800-2700hp | 2610kw 3500hp |

| Engine displacement | 50.25L | 60L | 77.6L |

| Bore/Stroke | 159×159 | 159×190 | 170×190 |

6. Highland Performance

• 16V4000 C23R 2500hp@1800rpm model, no power reduction at 5100m; no power reduction in the 5500m Julong field test;

• QSK60 2-stage supercharger, 2500hp@1900rpm, no power reduction at 3650m; 17% power reduction at 5500m;

16V4000C03 Standard daily maintenance cycle: Daily Maintenance

Replace every 500 hours, can be extended to 1000 hours maintenance; HEFF diesel filter system

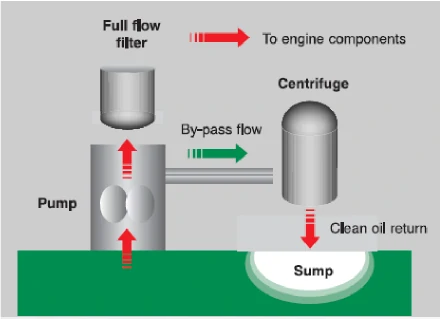

Centrifugal Oil filters 500hrs maintenance

Centrifugal Oil filters processes approximately 10% of the oilflow provided by the engine pump before returning it directlyto the engine sump.

• As Contaminant particle enter the rotor they are subjected to a centrifugal force causing them to migrate radially outwards to the inner surface of the rotor wall where, over time they compact to form a dense cake.

• Service interval of the oil centrifuges: approximately 500h

• Oil-change interval remains as-is

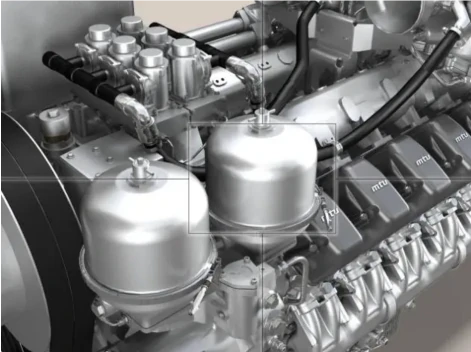

Centrifugal Oil filters 500-1000hrs maintenance

• Instead of spin-on filters, optional automatic filters with two oil centrifuges as standard

• Self-cleaning, maintenance-free

• Service interval of the oil centrifuges: approximately 500-1,000h

• Oil-change interval remains as-is

Safety: lower risk of dirt penetrating to the clean oil side of the engine during the process of changing filters

7.Warranty Terms

| 16V 4000 Cx3 | QSK 60- MCRS | |

|---|---|---|

| Engine | 5 years or 1 year no li | 2 years or 2,000hrs |

| Key parts | 3 years or 12,000hrs | 3 years or 10,000hrs |